Produktbeschreibung

MAHLE Motorsport "Power Pak" Kolben / Pistons TOYOTA 3SGTE 2.0L 90-95 MR2/Celica TURBO 86.50mm

High Tech Kolben aus dem Hause Mahle. Es handelt sich um ein komplettes Set mit Kolbenbolzen, Sicherungsringen, Kompressionsringen und Ölabstreifringen. Die Kolben sind Made in Germany und für den 3S-GTE Turbo Motor. Originalbohrung ist 86mm, diese Kolben sind für 86,5mm und somit Übermaßkolben. Die Kolben haben eine Spezielle Leichtlaufbeschichtung am Kolbenhemd (auf den Bildern schwarz) um Reibungsverluste und somit Verschleiß zu minimieren. Ein Kolben wiegt nur ca. 323 gramm, ein Originalkolben wiegt ca. 400 Gramm! Die Verdichtung mit diesen Kolben und Original Zylinderkopfdichtung ist 9:1.

Specifications:

- Bore Size: 86.5 mm

- Compression Height: 35 mm

- Compression Ratio: 9

- Material: M124 Alloy

- Pin Size (Diameter): 22 mm

- Rod Size: 138 mm

- Stroke Size: 86 mm

- Volume:-4 cc

- Weight: 323 g

About MAHLE Pistons

Every MAHLE MotorSport piston is backed by nearly 90 years of racing heritage and technology. From the invention of the first aluminium piston to the most advanced design and machining processes being used today, MAHLE delivers unmatched performance and durability. MAHLE's light-weight, low-drag design-specific forgings are machined with close attention given to ring groove quality, tolerances and consistency. All MAHLE pistons are dual-coated, adding protection and maintaining consistent performance over the life of the engine. These are just a few of the reasons why top professional race teams use MAHLE pistons. Rely on the technology leader, rely on MAHLE..

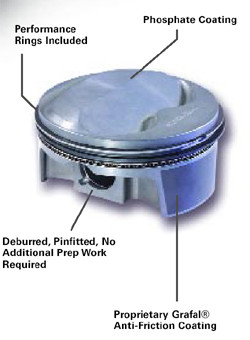

MAHLE Motorsport, the world leader in piston technology manufactures every piston with the same design features that win races and championships year after year. Through research and development partnerships with the OEM’s, as well as the worlds leading race teams, from F1 to NASCAR, MAHLE is constantly discovering new technologies that are incorporated into every piston we make. As a result, we’ve been able to introduce features like Finish Machined Pin Bores, Ultra Flat Ring Grooves, Slipper Skirt Forgings, Phosphate Coating and Grafal® Skirt Coatings. This is why they are so important:

Finish Machined Pin Bores - For superior performance

Piston failures can often be traced back to poor and inconsistent pin bore quality or design.

The pin bores on every MAHLE Motorsport piston are finish machined using CNC equipment to precisely control shape, size and alignment. As MAHLE designs and manufactures this specialist equipment, it is not available for any other piston manufacturer to purchase or use. This added control allows for advanced designs and flexibility, resulting in unmatched consistency and performance.

Ultra Flat Ring Grooves – They key to extra power. Every MAHLE Motorsport piston is machined to exacting tolerances with focused attention given to the radial flatness of the ring grooves. A flat ring groove is essential in achieving and maintaining the best seal possible. The quality of the ring grooves is so critical to peak and lasting performance, that MAHLE designed and built the machinery used to machine the ring grooves for its Motorsports pistons. Combined with ultra flat MAHLE rings that are included in every PowerPak piston kit, MAHLE delivers the formula for the best sealing pistons on the market.

Slipper Skirt Forgings - Not all forgings are equal. MAHLE Motorsport, creators of the “Slipper Skirt” forging design, uses strong, lightweight, low drag forgings in every PowerPak piston kit. Not all piston manufacturers can make that claim. A Slipper Skirt forging offers many benefits over the standard “Full Round” design, but the technology runs much deeper than looks alone. These benefits are only achieved through the proper management of the design; any misapplication can result in a similar looking part with poor performance. Trust the leader in piston technology - MAHLE Motorsport.

Grafal® Skirt Coatings - A true high performance coating. MAHLE’s proprietary Grafal® anti-friction skirt coating is like no other on the market. It is graphite impregnated to reduce drag like many other skirt coatings, but this is where the similarities end. The screen print application provides superior adhesion and is designed to last 100,000+ miles. Because Grafal® is a compressible membrane with a unique cushioning property, harsh contact between the piston skirt and the bore is dramatically reduced. This results in much less wear on the bore and significantly reduces piston skirt fatigue.

Phosphate Coating - A polished piston doesn’t mean a good piston. Phosphate coating provides the unique grey appearance to MAHLE pistons. This dry lubricant coating provides a lubricant film in the pin bores and ring grooves until the lubrication system of the engine reaches operating pressure. Particularly useful during the initial startup or break-in of engines to protect against galling and micro-welding. The piston crown can still be machined.

Bewertungen